Step 3.

Inspection

Technically speaking, this happens after every step of our process. We use precision tools such as our CMM to ensure that your parts are free of defects and measured to the correct specifications. At Maxima, quality control comes standard.

Step 4.

Capabilities

Once the designs have been inspected and the machines have been calibrated, our team can begin to manufacture your parts using an array of sophisticated equipment.

Milling

Nearly any shape is possible with 3, 4 and 5 axis. Scalable up to 80”(X axis), 30” (Y-axis) and 30” (Z-axis)

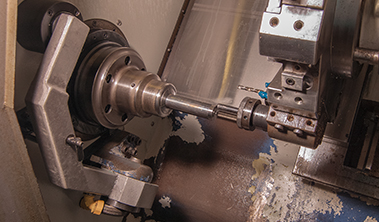

Turning

Commision symetrical parts with our double-spindle, 6-axis CNC Lathe - 6” in diameter and 36” long

Cutting

Fully equipped to resharpen tools, manufacture end mills, and ready to offer technical support for all of our products.

Step 5.

Assembly

After the parts have been manufactured, the last step is assembly. Each part is throughly tested for proper articulation after being fitted together in a clean environment. Additionally, we conduct another quality inspection to ensure we deliver the best possible product from start to to finish.

Ready for your quote?

Send us a little information and we’ll get back to you with an estimate.